Our Services

Drawing and Drafting

Grant Industrial understands that in a world with limited resources and component shortages you can be stuck in the position of having to update drawings, but your team does not have the bandwidth to do so. When those situations arise, let our experienced team of drafters provide you with an accurate updated drawing package freeing up your team’s time.

Need Your Design to Meet UL? We can Help

You just got a phone call from your customer stating the design they have submitted for their panel build now needs to be UL rated. With designs being created globally more each day, this is an increasingly common scenario, and one our engineers are experienced with. If your company requires assistance in aligning a drawing package with UL, Grant’s team of engineers can ensure you are in alignment.

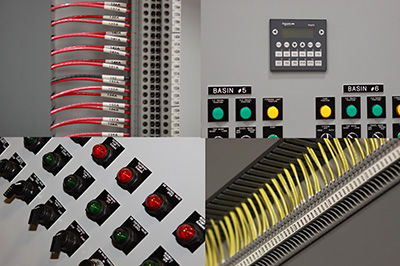

Assembled Product

For 40 years Grant has differentiated itself in electrical distribution with its ability to provide not only components but assembled solutions. From custom cord sets, alarm beacon assemblies and control stations to battery burn ins, software uploads and kitting, we have the know-how and experience to provide you the customer solution you need at the price you need to be at.

Custom Labels and Engraving

Grant has the ability to meet your labeling and engraving needs with our experience across multiple materials, techniques, font styles and abilities to import from multiple software platforms. Regardless your need, we will be able to make our mark.

Application Support

Our team of application engineers has over 50 years experience in supporting automation and control product across multiple industries. Whether you need assistance in troubleshooting existing equipment in the field, or with completing your new design our team is here to help.

Customized Training

With the speed new products are hitting the industry increasing more each year, staying on top of cutting edge offers and solutions is a challenge for everyone. Regardless your product focus, or industry segment, Grant can provide customized trainings for your team either at our facility or on site to ensure you are up to speed on the latest the industry has to offer.

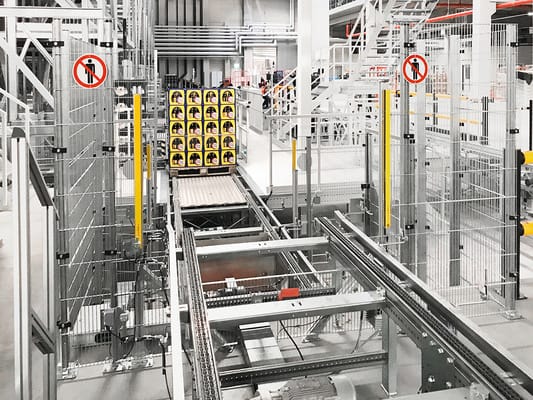

Risk Assessment Services

Whether dealing with a new installation or looking to evaluate your existing equipment or process, Grant Industrial Controls can assist with your risk assessment needs. Partnering with Leuze, we are able to provide one of the industry’s most comprehensive risk evaluations and a level of detail that will give you everything you need to determine how to keep your personnel safe and your process running smoothly. Find additional information on what these services include - Leuze Safety Services.

Value Add

Grant Idustrial Controls offers value-add solutions for our OEM customers in both our Pittsburgh and Erie location. Our value-add capabilities include:

Control Design, Inc.

Control Design Inc. acts as an extension to engineering companies and distributors. CDI manages your project from beginning to end; from component ordering and expediting through manufacture, test and packaging of your project. CDI, being a specialty manufacturer, is primarily a service business, selling the ability to manufacture customer products and projects. These projects include:

Your project can be manufactured from provided drawings and specifications, or from engineering sketches with formal drawings supplied by CDI. Through established relationships with local engineering teams, turnkey engineering can be provided with CDI participating in overall control system packaging and field installation. Control Design offers a complete drafting service including:

Please call Dave Nemcsik or Bill Russell a call at (412)-788-2280 for additional information on CDI’s capabilities, to request a quote or to schedule a visit.

CDI Custom Engraving and Marking Capabilities

Custom Engraving

Fonts & Symbols

Graphic Import File Types

Maximum Size